- Panki, Kanpur, Uttar Pradesh

- GST NO. : 09ABAFK1231C1ZZ

- View Primary Number

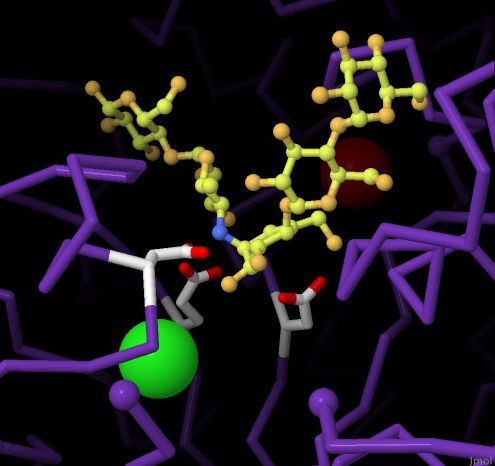

Enzymes

Leading Manufacturers, Exporters, Wholesaler and Trader of KOSAMYL G Sachharification Enzyme, KOSDEX- Dextranase Enzyme, KOSFERMN G Grain Fermentation Booster Enzyme, KOSLIQ G Liquefaction Enzyme, KOSNITRO G Nitrogen Substitute Enzyme, KOSPRES-B Heavy Preservation Enzyme and KOSTRCH- Starch Enzyme from Kanpur.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Purity | 99% |

| Type | Sachharification Enzyme |

| Country of Origin | India |

| Benefits | Increase of Hydrolysis Rate, Reduce Volatile Acidity |

| Doses | 4-5 ppm |

| Usage | Used By Bacteria in the Fermentation Process. |

Preferred Buyer From

| Location | All Countries Except India |

KOSAMYL G is Enzymes for saccharification of microalgal biomass such as cellulases, pectinases and amylases. Saccharification “to make into sugar” or the conversion, by enzymes, of starches into sugars and dextrins during the mashing process.

Benefits:

- Increase of hydrolysis rate

- lower enzyme requirement

- higher product yields

- Reduce volatile acidity.

- Improved fermentation efficiency by 2-3%

Recommended Application for best results:

- Doses - 4-5 ppm

| Business Type | Manufacturer, Exporter, Supplier, Trader |

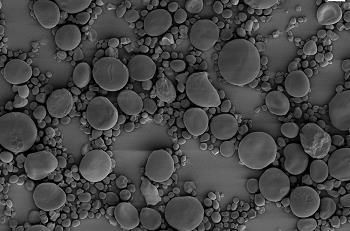

| Form | Powder |

| Application | Sugar Processing |

| Other Names | Dextranase Enzymes |

| Country of Origin | India |

| Recommended Dose | 3-4 ppm On Cane |

| Pack Size | 25 Kg |

| Pack Type | HDPE Drum |

| Benefits | Reduction in Dextran By 40-50%, Reduction in Molasses Purity |

Preferred Buyer From

| Location | All Countries Except India |

Dextran is a high molecular weight Polysaccharide. They are long chain molecules of simple sugar linked (α-1,6 glycosidic linkages) together either straight or branched manner but in a definite fashion.

Every unit of dextran eats 4 unit of sucrose causing higher sugar losses in molasses. In addition, the other losses are in terms of higher viscosity across the process, de-shaped sugar crystal formation, higher steam consumption, and clogging/blockage in pipelines. Also, the presence of such dextran results in the formation of organic acids and calcium salts which caused heavy scaling in heat exchangers.

Kosmic Global developed KOSDEX good product to reduce the dextran level by 40-60% in the processing.

Recommended dose- 3-4 ppm on Cane

Benefits:

- Reduction in dextran by 40-50%

- Reduction in Purity Drop & viscosity throughout processing

- Improved filterability &Improvement in mud settling.

- Reduction in molasses purity

- Improvement in purgebility at centrifugals & sugar quality.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Type | Grain Fermentation Booster Enzyme |

| Country of Origin | India |

| Benefits | Liquefaction At Lower pH, Helps to Reduce Viscosity |

| Doses | 4-5 ppm |

| Used for | Grain Base Feed Stock Distilleries |

Preferred Buyer From

| Location | All Countries Except India |

KOSFERMN G is a customized product for grain base feed stock distilleries. It converts non fermentable sugar into fermentable sugar. Also, eliminate bacterial growth. This is a thermostable enzyme, with excellent stability at low pH, which catalyzes the hydrolysis of alpha 1, 4 glycosidic linkages to quickly reduce the viscosity of gelatinized starch to yield dextrin and oligosaccharides under a variety of process

Benefits

- Liquification at lower pH

- Resistance to higher temperature

- Helps to reduce viscosity.

Recommended Application for best results:

- Doses - 4-5 ppm

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Type | Active Bacterial Derived Enzyme |

| Country of Origin | India |

| Benefits | High Ethanol Yield, Reduce viscosity, Reduced Bacterial Infection |

| Temperature Tolerance | 88-90 °c |

| Optimal Temperature | 50-60 °c |

| Doses | 0.2 – 0.25 Kg/mt of Dry Starch |

Preferred Buyer From

| Location | All Countries Except India |

KOSLIQ G is an active bacterially derived enzyme (α-amylase and amyl-glucosidase) that breaks down starch into smaller molecules called dextrin and simple sugars. It also improves results of liquefaction by cutting the complex carbon structure into smaller pieces, thus making it a liquid ready for further saccharification.

Benefits:

- High Ethanol yield

- Faster fermentation rate

- Reduce viscosity.

- Wider pH range tolerance

- Reduced bacterial infection.

Recommended Application for best results:

- Temperature Tolerance – 88-90 °C

- Optimal Temperature - 50-60 °C

- Doses - 0.2 – 0.25 Kg/MT of dry starch

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Form | Powder |

| Application | Sugar Processing |

| Type | Nitrogen Substitute Enzyme |

| Country of Origin | India |

| Replacement Of | Urea |

| Enzymatic Blend of | Nitrogen Source for Distilleries |

| Doses ( Grain) | 15-20 ppm |

| Doses (Molasses) | 5-10 ppm |

Preferred Buyer From

| Location | All Countries Except India |

KOSNITRO G product contains cocktail of enzymes which contribute a very excellent source of micro and macro nutrients. This is the best enzymatic blend of Nitrogen Source for Distilleries and replacement of Urea.

Benefits:

- 100% replacement of Urea, DAP, Magnisium and Zinc

- Easily degrades complex material by enzymatic acion.

- Increase cell multiplication by phosphate degradation

- Low treatment and low dosages

- Reduces overall process cost.

Recommended Application for best results:

- Doses ( Grain) - 15-20 ppm

- Doses ( Molasses) - 5-10 ppm

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Application | Sugar Processing |

| Type | Heavy Preservation Enzyme |

| Country of Origin | India |

| Benefits | Reduce Foaming Inside the Tank, Reduce Rapid Deterioration in Molasses |

| Recommended Dose- | 20 ppm per Mt |

Preferred Buyer From

| Location | All Countries Except India |

Bacterial contamination is known to be a major cause of reduction in ethanol yield during ethanol production from molasses because of sugar consumption by bacteria.

Bacteria like lactobacillus and Acetobactor convert the sugar content into volatile acids like Volatile acids, Lactic Acid and Acetic Acid and these can be controlled by applying KOSPRES-B enzyme at regular intervals.

KOSPRES-B is an excellent product which has been developed and formulated by Kosmic Global, especially for the sugar industry.

Recommended dose- 20 ppm per MT of molasses per month in case of B-Heavy and 15 ppm per MT of molasses in case of C-Heavy molasses

Benefits:

- Stop Maillard reaction in the storage tank

- Maintain total residue of sugar content.

- To reduce volatile acid content by 40-50%

- To reduce rapid deterioration in molasses.

- To control the fast reduction of TRS of molasses

- To preserve molasses from caramelization

- Reduce foaming inside the tank

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Application | Sugar Processing |

| Packaging Size | 25-50 Kg |

| Type | Starch Enzyme |

| Country of Origin | India |

| Benefits | To Reduce Pan Boiling Time, To Reduce the Turbidity of Juice |

| Recommended Dose | 4-5 Ppm On Cane |

Preferred Buyer From

| Location | All Countries Except India |

Starch is a natural polysaccharide going into the process along with cane juice. Starch contains a mixture of linear (amylose) and branched (amylopectin) structured components in a ratio of 20:80. Amylase and amylopectin both of which are polymers of glucose. Amylose is a polymer of glucose units linked together with α – 1 to 4 linkages. Amylopectin is a highly branched polymer in which beaches occur at α – 1 to 6 linkages.

The starch level ranges from 0.001% to 0.1% on juice solids. Starch level of approximately 0.005% on cane may cause serious operational problems.

Kosmic Global developed KOSTRCH good product to reduce the starch level by 50-60% in the processing.

Recommended dose- 4-5 ppm on Cane

Benefits:

- To improve capacity utilisation of the plant

- To reduce the turbidity of juice

- To improve the rate of crystallisation

- To reduce pan boiling time

- To reduce water consumption at centrifugals